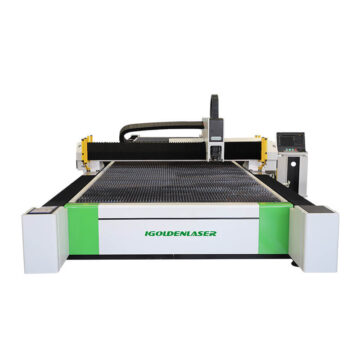

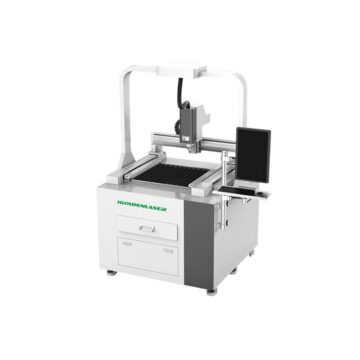

All in one laser cutting machine capable of cutting both sheets and profiles (including square tubes, round tubes, channel steel, angle steel). One machine with multiple functions, high cost performance. Cast iron bed, rack and pinion transmission system, professional CNC control system for automatic machining, high precision, full-featured, easy to use and simple to operate.

All in One Laser Cutting Machine

This machine is designed to handle both sheet metal and tube cutting tasks. It can accommodate different shapes and sizes of sheet metal, as well as round, square, rectangular, and other profiles of tubes. This versatility eliminates the need for multiple machines and reduces production time and costs.Compared with traditional laser sheet metal cutter and laser tube cutter, the all-in-one tube-sheet integrated laser cutting machine has fast cutting speed and high precision, which can realize the precision cuts of various special-shaped complex graphics that are difficult to achieve by conventional cutting tools.

All in One Laser Cutting Machinefor Sale

Fully enclosed sheet metal protection is a necessary safety measure for laser cutting machines, which can ensure the safety of operators, reduce environmental pollution, and improve production efficiency and equipment reliability.

Laser Source:Metal sheet and pipe laser cutting machines use a high-powered laser source, typically a fiber laser, to generate a focused laser beam. Fiber lasers are commonly used due to their high energy efficiency, excellent beam quality, and ability to cut a wide range of metal materials.

Metal sheet and pipe laser cutting machines offer design flexibility, allowing for intricate cuts, precise contours, and complex shapes. The CAD software provides the freedom to create custom designs and nest multiple parts on a single sheet, optimizing material usage and reducing waste.

Metal sheet and pipe laser cutting machines are typically equipped with user-friendly software interfaces that allow operators to program cutting parameters, import design files, and control the cutting process. The software may also include features for optimizing cutting paths, managing material inventory, and generating reports.

Laser cutting machines can be integrated into automated systems, allowing for continuous and high-volume production. The CNC system ensures precise and repeatable cutting results, even for complex geometries or tight tolerances. Some machines also feature automatic loading and unloading systems to further enhance productivity.

The cutting process begins with the CAD (Computer-Aided Design) software, where the desired shapes or patterns are designed. The CAD data is then transferred to the CNC (Computer Numerical Control) system of the laser cutting machine. The machine’s controller guides the laser beam along the programmed paths, melting and vaporizing the metal material. An assist gas, such as oxygen or nitrogen, is typically used to blow away the molten metal and create a clean cut.

A metal sheet and pipe laser cutting machine is a versatile and efficient tool used for cutting both flat metal sheets and cylindrical metal pipes or tubes. It utilizes laser technology to create precise and clean cuts on various types of metals.

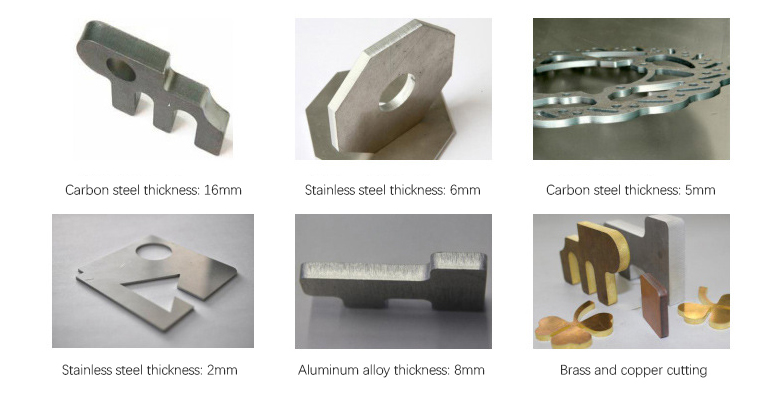

Laser Sheet Cutting: Metal sheet cutting is performed on a flat worktable where the metal sheet is securely clamped. The laser cutting machine moves the laser head and focuses the laser beam onto the sheet’s surface, following the programmed cutting path. The machine can cut various sheet metal materials, including stainless steel, carbon steel, aluminum, brass, copper, and more, with high precision and speed.

Laser Pipe Cutting: Metal pipe cutting is achieved using a specialized attachment or chuck that can hold and rotate the cylindrical pipe or tube. The laser cutting machine is equipped with a rotary axis, allowing it to cut along the pipe’s length or perform various angled cuts. Pipe cutting capabilities include straight cuts, bevel cuts, miter cuts, and even complex shapes or patterns. This process is commonly used in industries such as automotive, construction, furniture, and metal fabrication.

Fiber laser cutting provides high precision and accuracy, ensuring clean and smooth cuts with minimal heat-affected zones. This is particularly important for intricate designs and fine details.Many sheet metal and tube all-in-one fiber laser cutting machines come with advanced automation features. These include automatic loading and unloading systems, material handling systems, and software-controlled operations. Automation enhances productivity, reduces labor requirements, and improves overall efficiency.

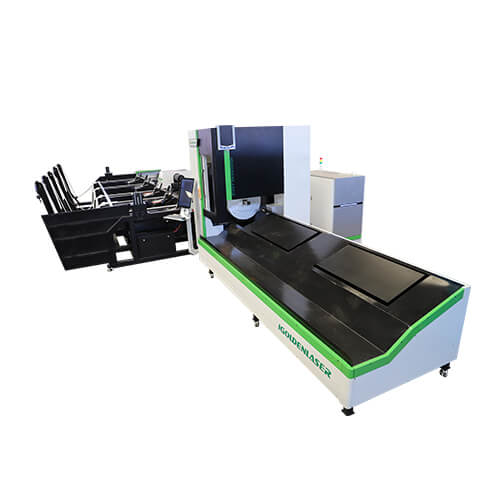

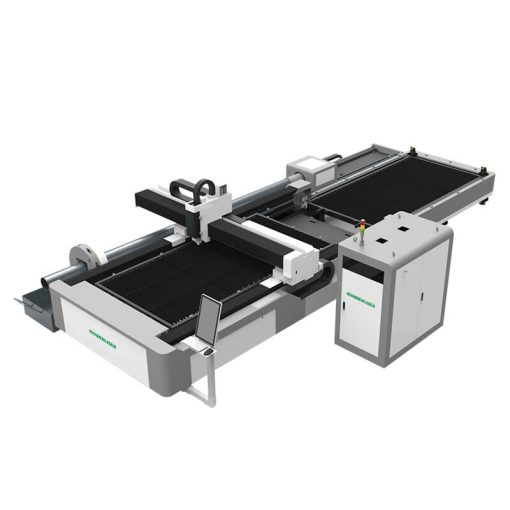

Exchange Platform Fiber Laser Cutting Machine

This is a dual-use fiber laser cutting machine with an exchange platform. It can cut both metal sheets and tubes, realizing two functions in one machine. Besides, the two worktables also help increase the working efficiency by 50%.

This metal laser cutter for steel is with a automatic exchange table, which will greatly improve the efficiency. During the main laser cutter for steel machine working, the workers can load the material on the exchange platform at the back. After the material feeding is completed, the exchange platform fiber laser cutting machine will automatically move the exchange table to the front, and the host laser cutter for steel machine will cut the workpiece on the exchange platform auxiliary table. The standard size of the exchange platform fiber laser cutting machine is 3000x1500mm, and can also accept customized working sizes of the machine.

- Plate and tube dual-purpose fiber laser cutting machine, can achieve the cutting of two different profiles on the same machine tool, can cut metal sheet and pipe (square pipe, round pipe, channel steel, Angle steel, etc.). The addition of the exchange platform, no need to wait for the blanking time, can maximize the production line rate, a multi-purpose machine, high cost performance, high precision, full function, easy to use.

- Optional laser power 1500W-6000W; Optional countertop 3015/4015/6015; 3 meter tube and 6 meter tube are standard.

- Support customization

Fiber Laser Tube Cutting Machine Application

Metal sheet laser cutting machines can cut a wide range of metals, even though highly reflective metals. For instance, carbon steel, stainless steel, aluminum, copper, brass, titanium, nickel, and various alloys. The sheet metal laser cutting machine has extensive applications in decoration, infrastructure, construction, microelectronic, advertising, kitchen appliance, automobile and other equipment manufacturing, and other industries.

Dual-use Metal Sheet Pipe Tube Laser Cutting Machine is designed for Circular(Round) Square Metal Pipe Tube Cutting and sheets cutting. Metal Tube Cutting Machine it adopts strong steel bed, rack drive system, professional pipe laser cutting CNC system, which ensure good cutting accuracy and efficiency of the CNC laser cutting machine. Over 3500 sets CNC fiber laser cutting machine have been sold to over 80 countries. Metal laser cutting machine is an ideal & high performance choice to cut metal tubes, plates and pipes for economic users.

Key Features of Metal Sheet, Pipe and Tube Laser Cutting Machine

- A metal sheet, pipe, and tube laser cutting machine is a specialized tool used in the manufacturing and metalworking industry for precisely cutting various types of metal materials. This machine uses a high-powered laser beam to cut through the metal, offering several advantages over traditional cutting methods, such as precision, speed, and the ability to cut intricate and complex designs. Here are some key features and aspects of a metal sheet, pipe, and tube laser cutting machine: Laser Source: The heart of the machine is the laser source, which typically uses either fiber laser or CO2 laser technology. Fiber lasers are popular for their high energy efficiency and ability to cut a wide range of metals, while CO2 lasers are suitable for non-metal materials and some metal cutting applications.

- CNC Control: The machine is equipped with computer numerical control (CNC) technology, which allows for precise control of the laser head’s movement and cutting parameters. This ensures accurate and repeatable cuts.

- Cutting Capabilities:Metal Sheets: These machines can cut flat metal sheets, such as steel, aluminum, and stainless steel. They are often used for creating parts for various industries, including automotive, aerospace, and electronics. Pipes and Tubes: Some laser cutting machines are equipped with rotary axes that enable the cutting of cylindrical or tubular metal objects like pipes and tubes. This is common in industries like construction, HVAC, and furniture.

- Precision and Accuracy: Laser cutting machines provide high levels of precision and accuracy, with minimal heat-affected zones, which reduce the risk of material distortion.

- Versatility: These machines can cut various thicknesses of metal, from thin sheets to thick plates, depending on the laser source’s power and the machine’s configuration.

- Speed and Efficiency: Laser cutting is generally faster than traditional cutting methods, making it more efficient for high-volume production.

- Automation: Some machines are equipped with automatic loading and unloading systems, which further enhance productivity by reducing manual labor.

- CAD/CAM Integration: Laser cutting machines are often integrated with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing users to design parts and convert those designs into cutting programs.

- Safety: Laser cutting machines incorporate safety features such as enclosures, exhaust systems, and safety interlocks to protect operators from laser radiation and fumes.

- Maintenance: Regular maintenance is essential to keep the machine operating at peak efficiency. This includes cleaning the optics, inspecting and replacing consumable parts, and ensuring proper alignment.

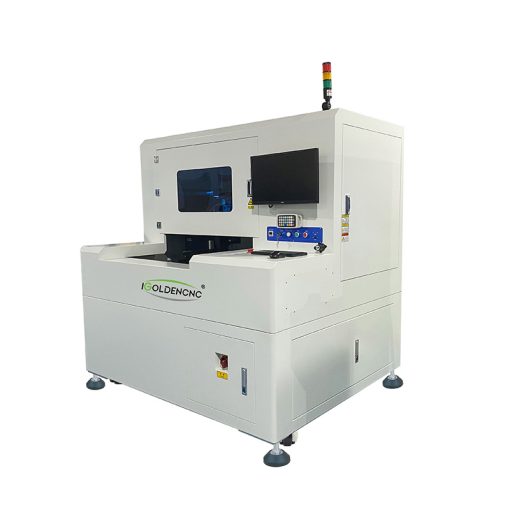

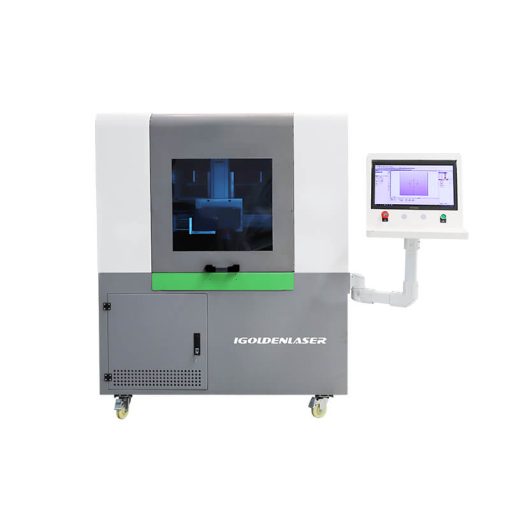

A stainless steel laser engraving machine is a type of equipment that uses a laser beam to etch designs or text onto stainless steel surfaces. The machine works by directing a high-powered laser beam onto the surface of the stainless steel, which vaporizes the material and creates a permanent mark. Stainless steel laser engraving machines are commonly used in industrial and manufacturing applications to add branding or identification information to products made of stainless steel.

Our Stainless Steel Laser Engraving Machine is a state-of-the-art solution designed specifically for engraving and marking stainless steel materials. With its advanced laser technology and precision control, this machine offers exceptional engraving capabilities, allowing you to create intricate designs, logos, text, and more on stainless steel surfaces.They are also used in the jewelry industry to engrave custom designs onto stainless steel jewelry.

When selecting a stainless steel laser engraving machine, it is important to consider factors such as the size of the machine, the power of the laser, and the level of precision required for the engraving. Some machines may also offer additional features such as rotary attachments for engraving cylindrical objects or software for creating and editing designs.

Stainless Steel Laser Engraving & Cutting Machine Product Features:

- High-Power Laser Source: Equipped with a high-power laser source, this machine delivers the energy required for deep engraving on stainless steel. It ensures consistent and precise results, even on challenging materials.

- Versatile Engraving Options: The Stainless Steel Laser Engraving Machine offers a wide range of engraving options, including surface etching, deep engraving, annealing, and color marking. It provides flexibility to meet different engraving requirements and achieve desired effects.

- Precision and Accuracy: With advanced laser technology and precise control, this machine ensures precise positioning and accurate engraving, resulting in sharp and well-defined marks. It can handle intricate designs and small details with exceptional clarity.

- User-Friendly Interface: The machine features a user-friendly interface that allows for easy operation and parameter adjustment. The intuitive software enables quick design setup and provides real-time preview, ensuring optimal engraving outcomes.

- Integrated Cooling System: The Stainless Steel Laser Engraving Machine is equipped with an integrated cooling system that effectively dissipates heat during prolonged engraving sessions. This ensures stable performance and extends the lifespan of the machine.

- Compatibility with Various Stainless Steel Grades: This machine is compatible with a wide range of stainless steel grades, including 304, 316, 430, and more. It can engrave on both polished and matte surfaces, offering versatility for various applications.

Laser Engraving Machine Advantages:

- Permanent and Durable Markings: Laser engraving on stainless steel creates permanent markings that are highly resistant to wear, corrosion, and fading. The engraving penetrates the surface, ensuring long-lasting durability, making it ideal for industrial, commercial, and decorative applications.

- High-Speed Engraving: The Stainless Steel Laser Engraving Machine delivers high-speed engraving capabilities, enabling efficient production and reducing turnaround time. It is suitable for both small-scale customization and large-scale industrial applications.

- Customization and Personalization: With this machine, you can easily add custom designs, serial numbers, logos, and personalized text on stainless steel products. It offers endless possibilities for customization, making it ideal for promotional items, gifts, signage, and branding purposes.

- Non-Contact Engraving: Laser engraving is a non-contact process, eliminating the need for physical contact with the stainless steel surface. This minimizes the risk of scratches, damage, or contamination, ensuring clean and pristine engravings.

- Wide Range of Applications: The Stainless Steel Laser Engraving Machine finds applications in various industries, including automotive, aerospace, jewelry, electronics, kitchenware, and more. It can engrave on a wide array of stainless steel products, such as tags, nameplates, components, utensils, and appliances.

- Cost-effective Solution: Laser engraving offers a cost-effective solution compared to traditional engraving methods. It eliminates the need for consumables like ink or cutters and reduces setup time. Additionally, it allows for high repeatability, minimizing material waste and optimizing production efficiency.

Unleash Your Creativity with Stainless Steel Laser Engraving: Our Stainless Steel Laser Engraving Machine empowers you to create stunning and permanent engravings on stainless steel materials. Experience the precision, versatility, and efficiency of laser engraving, and elevate your products and designs to new heights.

Contact us today to discover how this advanced technology can enhance your engraving capabilities and meet your unique business needs.

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINE10kw 12kw Laser Cutting Machine for Metal Sheet

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINECNC Metal Laser Cutting Machine

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEDual-use Fiber Laser Cutter for Metal Sheet and Tube

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEFiber Laser Cutting Machine for Matel

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEFiber Laser Tube Cutting Machine for Metal Tubes of Various Shapes

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEFlatbed Fiber Laser Cutting Machine 1530 for Metal Sheet Cutting

-

LASER CUTTER

LASER CUTTERHigh Precision Small Metal Laser Cutting Machine for Home

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEIndustrial Laser Cutting Machine For Metal With Exchange Table

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEMetal Pipe Laser Cutting Machine with Automatic Feeding Device

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEMetal Tube Sheet Laser Cutting Machine Exchange Table

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEProtective Fiber Laser Cutter Machine with CE Certificate

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINETube & Sheet Laser Metal Cutting and Engraving Machine

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINETube Laser Cutter for Metal Pipe Laser Cutting Machine

-

LASER CUTTER, LASER MACHINE

LASER CUTTER, LASER MACHINEUltra High Power Metal Laser Cutting Machine

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

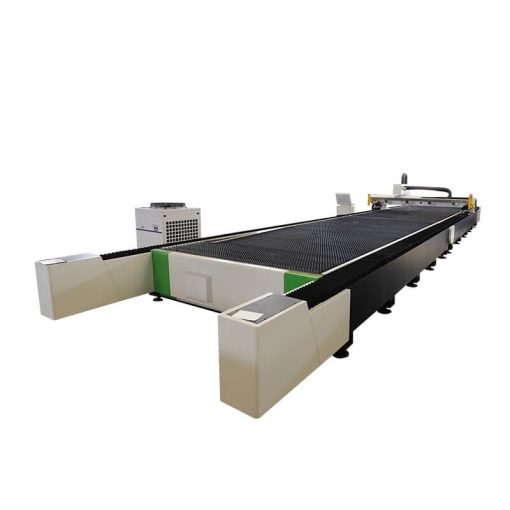

New Design High Power Large Format Laser Cutting Machine for Sale

LASER CUTTING MACHINE

LASER CUTTING MACHINE

LASER CUTTING MACHINE

Metal Sheet and Pipe Laser Cutting Machine with Exchange Worktable

LASER CUTTING MACHINE