5 axis CNC stone cutting bridge saw adopts an automatic computer control system, which can realize manual programming or CNC programming and other programming methods to automatically complete cutting operations. It can conveniently perform horizontal cutting, longitudinal cutting, arc cutting, elliptical cutting, round cutting, arbitrary angle cutting, concave-convex edging, shaped cutting, special-shaped processing and more occasions with powerful functions.

5 Axis Bridge Saw

5 axis CNC bridge saw is an automatic stone machining equipment that can complete the processing of pentahedron special-shaped curved surfaces at one time through five-axis linkage control, that is, three linear moving axes and two rotating axes.

It is a type of Automatic CNC Machine tailor-made for the majority of stone fabricators by IGOLDENCNC in order to meet the cutting plans of stone machining manufacturers. It has various processing modes of cutting, milling, engraving, and drilling. The bridge saw features with multiple functions, small footprint, simple operation, precise cutting, quick and convenient conversion of different functions.

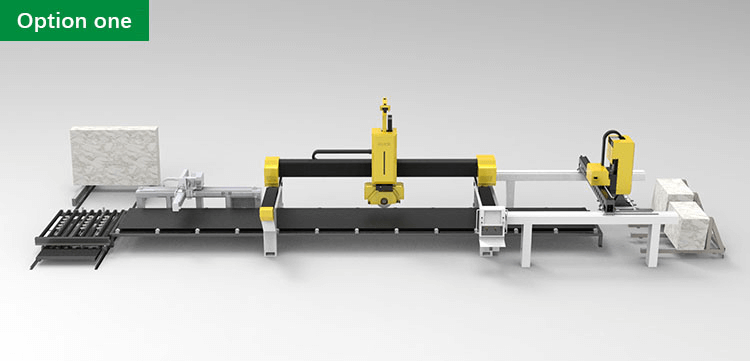

5 Axis CNC Marble Stone Bridge Saw Machine Assembly Line

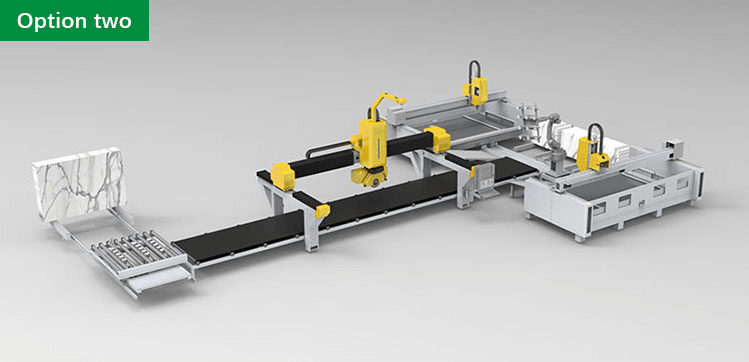

5 Axis CNC Bridge Saw Machine Quartz Slab Production Line for Stone Cutting and Polishing

What Can 5 Axis CNC Cutting Bridge Saw Do?

The 5 axis CNC bridge saw can cut any shape of stone lines, arc edges, duckbill edges, straight edges, beveled edges, non-slip grooves, dry hanging grooves, sink processing, and special-shaped edge forming.

- 1. Countertop cut: blank slab cutting, rear gear cutting, reverse buckle cutting, hanging material, L-shaped table to length, corner cutting reserved, 45-degree chamfered front mouth, pot hole, stove hole, Diagonal line cutting, cutting at any angle of the wall crenel.

- 2. Automatic cut: Realize the import of CAD drawings, cutting completely according to the drawing style, no need to enter complex data.

- 3. Bridge cut: It has all the functions of bridge cutting equipment on the market.

- 4. Roman column cut: Cut the square Roman column main board and both sides at one time, and simultaneously chamfer 45 degrees on both sides to complete the Roman column hole cutting.

- 5. Arc-shaped line cut: Install the line grinding head to complete the arc-shaped line shape, and cut into a rough arc-shaped line as a whole, which requires manual polishing.

- 6. Concave-convex cut: According to the arc, grind out the desired convex or concave plate. It is mainly used for grinding and making curved plates of special-shaped background walls or special-shaped decorative panels.

- 7. Abnormity cut: To solve the problem of uneven walls, cut out asymmetric quadrilaterals or isosceles trapezoids.

Bridge Stone Saw Application

The 5 axis CNC stone bridge saw is good at cutting, milling, chamfering and edging quartz, marble, artificial stone and slabs in regular and irregular shapes. It can realize countertop cutting, bridge cutting, roman column cutting, arc line cutting, concave-convex cutting, and irregular edge cutting and milling. The automatic stone cutting bridge saw can process products of sanitary ware, stone furniture, interior decoration, and other fields. For example, wash basins, bathroom countertop, stone tables, dinning tables, kitchen tables, kitchen cabinet basins, background wall, roman edge stone decorations, etc.

Features of 5 Axis CNC Stone Cutting Bridge Saw for Countertop with Granite, Marble, Quartz

Through the optimization of the process parameters by the numerical control system, the product data files can be stored in modules and called manually. The ideal effect of extremely coordinated movement of each precision component is realized. The process of machine cutting stone slabs can realize automatic and intelligent cutting of stone materials through the pre-setting of the cutting coding program and the automatic operation of the cutting process, so as to achieve the mass production of stone slabs.

1. The integrated design gives the machine more advantages, such as occupying small space, easy installation and debugging, high precision, stable performance, easy operation and so on.

2. Bridge, sliding rails and blade holder are built in strong and stiff cast iron for stability, durability and low resonance.

3. Cutting head rotate 90°, tilting 45° suitable for chamfering cutting.

4. 0° to 360° cutting head rotation and 0° to 90° cutting head tilting.

5. The worktable installs independently, the hydraulic console panel level 0, 45°, 90° turns. Worktable tilting vertical turn 85°, easier and safe loading raw materials.

6. The CNC bridge saw is made up of main motor, longitudinal slicing part, worktable assembly, electric control system, hydraulic system and so on.

7. The CNC bridge saw is equipped with infrared tool setting gauge, to accurately adjust the cutting size.

8. Once all the parameters are well setting, it is not necessary to have workers watching on machine. It will automatically stop once it finishes the cutting. It is an ideal automation equipment of stone slab cutting machine.

RELATED PRODUCT

-

Best Stone CNC Machining Center For Cutting And Polishing

-

Bridge Saw Machine 4-Axis And 5 Axis For Granite Marble

-

Kitchen Countertop Granite Stone Cutting Bridge Saw

-

New CNC Bridge Saw for Granite & Marble Stone Cutting Machine

How Does 5 Axis CNC Bridge Saw Works?

5 axis CNC bridge saw adopts a PC-based five-axis linkage numerical control system for stone machining. The tool is controlled by three linear axes and two rotary axes, and the two rotary axes rotate around the X axis and the Z axis respectively. The automatic function of cutting, engraving and milling with complex pentahedral features is mainly used for the processing of high-quality stone decoration with complex surfaces in multi-dimensional space. The stone industry has undergone many product technological changes. The technical characteristics and advantages of the processing equipment whose tool motion trajectory is controlled by 5-axis and 6-axis linkages are becoming more and more obvious. The CNC five-axis bridge stone cutting machine is a professional stone machining equipment with outstanding flexible manufacturing ability and high automation, which uses a diamond disc saw blade as the main cutting tool.

4 Axis 5 Axis CNC Bridge Saw Machine

Bridge saw machine is a type of stone cutting machine designed for diversified stone business. And CNC stone bridge cutters are cutting machines made for cutting natural stone, granite, marble, and ceramics. With a CNC stone saw, it is good at special-shaped cutting, polishing, edging, drilling, and chamfering of granite, marble, quartz, artificial stone, and natural stone. Therefore, it is also known as stone bridge saw cutting machine, stone bridge saw for quartz, bridge saw for granite, tile bridge saw, marble bridge cutting machine, stone bridge saw cutter, etc.