In the fast-paced world of manufacturing, precision, and efficiency are paramount. As industries strive to maintain high-quality standards while maximizing productivity, Vision Systems has become a game-changer. At Profile Solutions USA, we are committed to delivering cutting-edge Vision Systems that enhance operational efficiency and ensure superior product quality.

What Are Vision Systems?

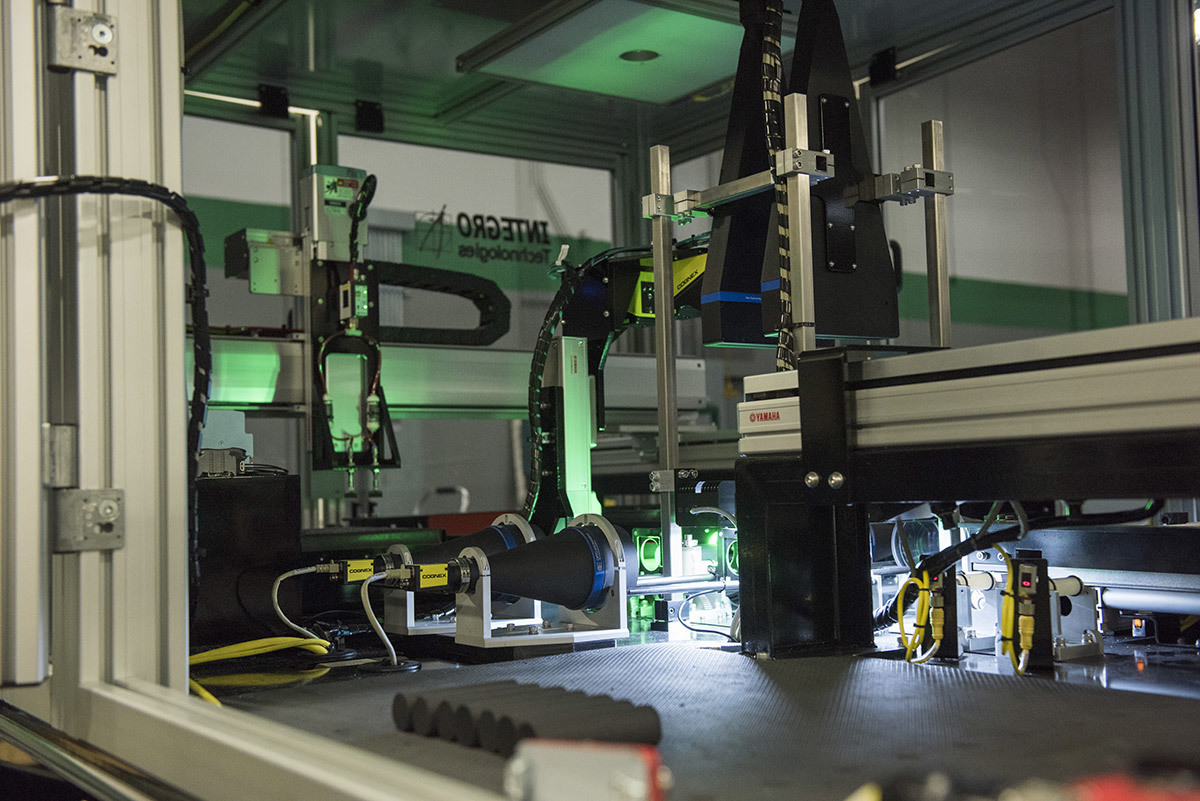

Vision Systems are advanced technology solutions that utilize cameras, sensors, and software algorithms to inspect, monitor, and analyze various aspects of the manufacturing process. These systems can be integrated into production lines to perform tasks such as quality control, measurement, sorting, and identification with unmatched accuracy and speed.

The Benefits of Vision Systems in Manufacturing

- Improved Quality Control: Vision Systems are designed to detect even the slightest defects in products, ensuring that only high-quality items make it through the production line. This leads to a significant reduction in the number of defective products, saving time and resources.

- Increased Efficiency: By automating inspection processes, Vision Systems can operate at speeds far beyond human capability. This means faster production rates without compromising on quality.

- Cost Savings: Implementing Vision Systems can lead to substantial cost savings by reducing waste, minimizing rework, and lowering labor costs associated with manual inspections.

- Enhanced Flexibility: Vision Systems are versatile and can be adapted to different products and processes. Whether you need to inspect small electronic components or large automotive parts, these systems can be customized to meet your specific needs.

- Data-Driven Insights: Vision Systems not only perform inspections but also collect valuable data that can be analyzed to identify trends, optimize processes, and make informed decisions. This data-driven approach leads to continuous improvement in manufacturing operations.

Applications of Vision Systems

Vision Systems are widely used across various industries, including:

- Automotive: Inspecting parts and assemblies for defects, measuring dimensions, and ensuring proper alignment.

- Electronics: Verifying the placement of components on PCBs, inspecting solder joints, and detecting surface defects.

- Pharmaceuticals: Checking packaging integrity, verifying labels, and ensuring that products meet regulatory standards.

- Food and Beverage: Monitoring product quality, inspecting packaging, and ensuring compliance with safety regulations.

Why Choose Profile Solutions USA?

At Profile Solutions USA, we pride ourselves on providing state-of-the-art Vision Systems tailored to the unique needs of our clients. Our systems are designed to integrate seamlessly into your existing production lines, offering reliable performance and exceptional accuracy.

We understand that every manufacturing process is different, which is why we offer customized solutions that cater to your specific requirements. Our team of experts works closely with you to understand your challenges and develop Vision Systems that enhance your operational efficiency and product quality.

Conclusion

Investing in advanced Vision Systems from Profile Solutions USA is a smart decision for any manufacturing business looking to improve quality control, increase efficiency, and reduce costs. With our cutting-edge technology and commitment to customer satisfaction, we help you stay ahead of the competition and achieve your production goals.

Contact us today to learn more about how our Vision Systems can revolutionize your manufacturing process.