In the powerful universe of manufacturing, industrial Toü automation has arisen as a foundation for proficiency, efficiency, and seriousness. The Assembled Kingdom, with its rich industrial legacy and obligation to mechanical headway, remains at the front of adopting and innovating industrial automation arrangements. From mechanical arms to cutting edge sensors, the UK market offers a different scope of automation parts catering to different industries. We should dive into the scene of industrial automation parts in UK, exploring key parts, patterns, and the job they play in shaping the fate of manufacturing.

Advancement of Industrial Automation Parts

The development of industrial automation in the UK has been set apart by huge progressions in innovation and a shift towards additional integrated and intelligent frameworks. Customary manufacturing processes have given approach to computerized arrangements, driven by elements like the requirement for higher accuracy, increased efficiency, and cost-viability.

Key parts of industrial automation include:

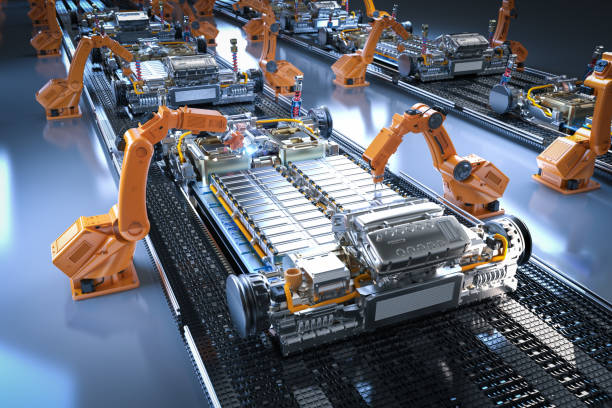

Mechanical Frameworks: Automated arms and computerized directed vehicles (AGVs) are generally utilized in manufacturing offices for undertakings ranging from gathering and material handling to welding and painting. Cooperative robots (cobots) have gained ubiquity for their capacity to work close by human administrators, enhancing adaptability and wellbeing on the shop floor.

Sensors and Instrumentation: Sensors assume a pivotal part in automation by providing continuous information on boundaries like temperature, tension, moistness, and movement. High level sensor innovations, including IoT-empowered gadgets and machine Homeworkify vision frameworks, empower prescient maintenance, quality control, and interaction enhancement.

Programmable Rationale Regulators (PLCs): PLCs structure the foundation of industrial automation, controlling machinery and cycles through advanced and simple inputs and results. These adaptable gadgets are programmable and can be tweaked to suit explicit applications across assorted industries.

Movement Control Frameworks: Movement control frameworks direct the development of machinery and gear, ensuring exact positioning and synchronization. Servo drives, stepper engines, and linear actuators are fundamental parts in robotized manufacturing processes, enabling rapid and high-exactness activities.

Human-Machine Interface (HMI): HMIs furnish administrators with a graphical interface to screen and control industrial cycles. Touchscreen shows, administrator boards, and programming interfaces work with intuitive interaction, improving functional productivity and reducing mistakes.

Patterns Shaping the Industry

The industrial automation area in the UK is portrayed by a few striking patterns that are reshaping the scene of manufacturing:

Industry 4.0 and Shrewd Manufacturing plants: Industry 4.0 initiatives are driving the integration of automation, information investigation, and network to make savvy industrial facilities. IoT-empowered gadgets, distributed computing, and computerized reasoning (man-made intelligence) are transforming customary manufacturing offices into light-footed and responsive conditions equipped for independent direction and prescient maintenance.

Advanced Twins and Recreation: Computerized twin innovation, which involves creating virtual imitations of actual resources and cycles, is gaining footing in industrial automation. By simulating creation situations and optimizing work processes in a virtual climate, makers can minimize free time, lessen costs, and speed up chance to-showcase.

Sustainable Manufacturing Practices: With growing worries about natural sustainability, producers are increasingly adopting automation answers for upgrade energy utilization, decrease waste, and improve asset effectiveness. Brilliant sensors and energy the board frameworks empower constant monitoring and control of energy use, contributing to a greener and more sustainable manufacturing environment.

Store network Versatility and Restriction: The Coronavirus pandemic featured the weaknesses of worldwide stockpile chains, prompting a reconsideration of sourcing methodologies and a shift towards limitation. Automation advancements, including mechanical technology and independent operations frameworks, are being conveyed to upgrade store network flexibility, further develop inventory the executives, and minimize disturbances.

Job in Driving Seriousness

Industrial automation assumes a significant part in driving seriousness and fostering innovation across industries in the UK:

Upgraded Efficiency: Via automating dull undertakings and streamlining creation processes, industrial automation further develops efficiency and functional productivity, allowing makers to satisfy growing need while reducing costs.

Quality and Consistency: Automation guarantees steady quality and accuracy in manufacturing, minimizing imperfections and fluctuation. More tight command over creation boundaries brings about better items that meet or surpass client assumptions.

Nimbleness and Adaptability: Mechanized frameworks empower quick reconfiguration and transformation to changing business sector requests, providing makers with the spryness to scale creation, introduce new items, and answer emerging patterns quickly.

Gifted Labor force Advancement: While automation diminishes the requirement for difficult work in certain errands, it likewise sets out open doors for upskilling the labor force in regions like programming, maintenance, and information examination. Training programs and instructive initiatives are fundamental for empowering laborers to bridle the maximum capacity of automation advancements.

End

The scene of industrial automation parts in the UK is portrayed by innovation, integration, and a constant quest for productivity and seriousness. From mechanical frameworks and sensors to cutting edge control frameworks and advanced twins, automation innovations are transforming the manufacturing area, driving efficiency, sustainability, and flexibility. As industries continue to advance and embrace computerized change, the UK remains at the very front of shaping the eventual fate of manufacturing through innovative automation arrangements.