A pressure transducer is an essential tool in many industrial and scientific applications. Its primary function is to convert pressure into an electrical signal. This transformation is crucial in various fields, including automotive, aerospace, and medical industries. Let’s delve deeper into what a pressure transducer is, how it works, and its applications.

What is a Pressure Transducer?

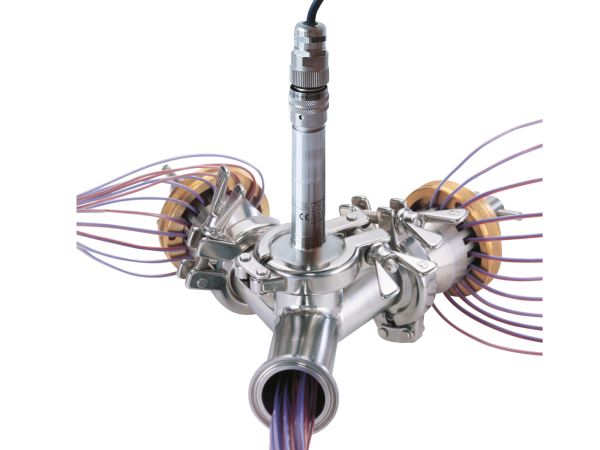

A pressure transducer, sometimes known as a pressure sensor, is a device that measures the pressure of gases or liquids. Pressure is an essential parameter in many processes, and accurate measurement is critical for efficiency and safety. A pressure transducer takes physical pressure and converts it into an electrical signal that can be read and analyzed.

How Does a Pressure Transducer Work?

The working principle of a pressure transducer involves several components. Firstly, it has a sensing element that responds to pressure changes. This element can be a diaphragm, a piezoelectric crystal, or a strain gauge. When pressure is applied, the sensing element deforms, creating a measurable change.

This change is then converted into an electrical signal. For instance, in a strain gauge transducer, the deformation causes a change in electrical resistance. This resistance change is proportional to the pressure applied, allowing for precise measurements.

Types of Pressure Transducers

There are several types of pressure transducers, each suited for different applications. The most common types include:

- Strain Gauge Transducers: These are widely used due to their accuracy and reliability. They work by measuring the change in resistance of a strain gauge attached to a diaphragm.

- Capacitive Pressure Transducers: These devices measure pressure changes by detecting variations in capacitance between two plates.

- Piezoelectric Transducers: These transducers utilize piezoelectric materials that generate an electric charge when subjected to mechanical stress.

- Optical Pressure Transducers: These use light to measure pressure changes. They are highly sensitive and often used in environments where electromagnetic interference is a concern.

Applications of Pressure Transducers

Pressure transducer have a broad range of applications across various industries. Here are some notable examples:

Automotive Industry

In the automotive sector, pressure transducers are crucial for monitoring and controlling engine performance. They help in measuring fuel pressure, oil pressure, and turbo boost pressure. By providing real-time data, these sensors ensure optimal engine operation and prevent potential damage.

Aerospace Industry

In aerospace, pressure transducers are vital for monitoring cabin pressure, hydraulic systems, and fuel systems. Accurate pressure measurement is essential for the safety and efficiency of aircraft operations. These sensors are designed to withstand extreme conditions, including high altitudes and rapid pressure changes.

Medical Industry

Pressure transducer play a significant role in medical devices, particularly in monitoring blood pressure. They are used in critical care equipment like ventilators and infusion pumps, ensuring precise control and monitoring of vital parameters.

Industrial Applications

In industrial settings, pressure transducers are used in various processes, such as monitoring and controlling pressure in pipelines, tanks, and reactors. They are essential in ensuring the safe and efficient operation of equipment and processes.

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, pressure transducer monitor and control the pressure of refrigerants. This ensures the systems operate efficiently and maintains a comfortable environment.

Advantages of Pressure Transducers

Using pressure transducers offers several benefits. Here are some key advantages:

Accuracy and Precision

Pressure transducer provide highly accurate and precise measurements. This is crucial in applications where even slight deviations can have significant consequences.

Real-time Monitoring

These devices enable real-time monitoring of pressure, allowing for immediate adjustments and responses to changes. This real-time capability is essential in critical applications such as medical devices and aerospace systems.

Versatility

Pressure transducers are versatile and can be used in a wide range of applications. They are available in various types and configurations, making them suitable for different environments and requirements.

Durability

Many pressure transducer are designed to withstand harsh conditions, including high pressure, extreme temperatures, and corrosive environments. This durability ensures reliable performance over time.

Compact Size

Modern pressure transducers are compact and lightweight, making them easy to integrate into existing systems without significant modifications.

Choosing the Right Pressure Transducer

Selecting the appropriate pressure transducer for a specific application involves considering several factors:

Pressure Range

Ensure the transducer can handle the expected pressure range of your application. Using a sensor with an insufficient range can lead to inaccurate readings or damage.

Accuracy Requirements

Determine the level of accuracy required for your application. High-precision applications may need transducers with tighter tolerances.

Environmental Conditions

Consider the environmental conditions where the transducer will be used. Factors such as temperature, humidity, and exposure to corrosive substances can affect the performance and longevity of the sensor.

Output Signal

Choose a transducer with an output signal compatible with your system. Common output signals include voltage, current, and digital signals.

Installation and Maintenance

Evaluate the ease of installation and maintenance. Some transducers require regular calibration and maintenance to ensure accurate performance.

Future Trends in Pressure Transducers

The field of pressure transducer is continually evolving, with advancements in technology leading to improved performance and new applications. Here are some trends to watch:

Integration with IoT

The integration of pressure transducers with the Internet of Things (IoT) is becoming increasingly common. This allows for remote monitoring and control, enhancing efficiency and enabling predictive maintenance.

Miniaturization

Advancements in manufacturing techniques are leading to smaller and more compact pressure transducers. These miniature sensors can be used in applications where space is limited, such as in medical devices and portable equipment.

Enhanced Sensitivity and Accuracy

Ongoing research is focused on developing materials and designs that enhance the sensitivity and accuracy of pressure transducer. This is particularly important in fields like aerospace and healthcare, where precision is critical.

Wireless Technology

The adoption of wireless technology in pressure transducers is on the rise. Wireless sensors offer greater flexibility in installation and can reduce the complexity and cost of wiring in large systems.

Conclusion

Pressure transducer are indispensable tools in modern technology. Their ability to convert pressure into readable electrical signals is vital in many industries. As technology advances, pressure transducers will continue to evolve, offering greater precision, reliability, and versatility. Whether in automotive, aerospace, medical, or industrial applications, these sensors play a crucial role in ensuring safety, efficiency, and performance. Understanding their operation, types, and applications can help in selecting the right transducer for any specific need.