Introduction

A fruitful automation factory model is based on efficiency, versatility, and advanced innovations. Whether you’re designing for a certifiable manufacturing arrangement or a recreation game, focusing on key elements will guarantee smooth tasks and long haul achievement.

Outline

Introduction

Key Elements of a Fruitful Automation Factory Model

Adaptable Layout Design

Advanced Automation Innovation

Resource Improvement

Secluded Production Units

Information Driven Independent direction

Challenges in Achieving Automation Efficiency

Conclusion

FAQs

Background: Key Elements of a Fruitful Automation Factory Model

A very much designed automation factory ought to have the option to scale as production demands increase and integrate advanced automation systems for ideal efficiency. It likewise needs to guarantee resource use is upgraded and free time is minimized. Here are the top highlights that make an automation factory model fruitful.

Key Elements of a Fruitful Automation Factory Model

1. Adaptable Layout Design

An adaptable factory layout considers simple variation to new cycles and increases in production volume. Whether you are adding new machines or reconfiguring the work process, the layout ought to help changes without significant interruptions.

Tip: Utilize a particular layout where production lines can be stretched out or re-steered to oblige new systems or innovations.

2. Advanced Automation Innovation

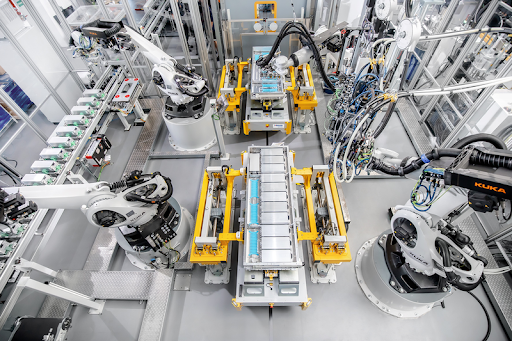

Incorporating the most recent automation innovations — like mechanical arms, mechanized transport systems, and simulated intelligence driven control systems — guarantees greatest efficiency. Automation decreases human mistake and velocities up production, allowing for more steady result.

Tip: Invest in advances that are scalable and can be refreshed as new innovations arise.

3. Resource Improvement

A fruitful factory model enhances the utilization of natural substances, energy, and human resources. Minimizing waste, maximizing result, and ensuring energy-efficient production is fundamental.

Tip: Screen resource use intently and change production cycles to guarantee sustainability and cost-efficiency.

4. Particular Production Units

Dividing the factory into particular production units considers more straightforward scaling. As demand develops, production units can be copied or acclimated to meet the increased responsibility without overhauling the whole framework.

Tip: Design every module to work independently while as yet being ready to integrate flawlessly with the remainder of the framework.

5. Information Driven Direction

Leveraging continuous information and analytics to drive dynamic cycles is basic in optimizing activities. Mechanized systems ought to be integrated with information analytics instruments to screen performance and recognize expected issues before they become basic issues.

Tip: Carry out an incorporated information framework to gather and analyze production information, helping to foresee maintenance needs, streamline production plans, and manage inventory.

Challenges in Achieving Automation Efficiency

High Initial Expenses: The forthright expense of implementing advanced automation innovations can be high, yet long haul savings and efficiency gains as a rule offset the initial investment.

Maintenance Necessities: Mechanized systems require customary maintenance to forestall personal time, which can be challenging for processing plants operating all day, every day.

Integration Intricacy: As you scale and introduce more mechanized systems, integrating them easily into existing work processes can turn out to be increasingly perplexing.

Conclusion

A fruitful automation factory model depends on a combination of adaptable layouts, cutting-edge innovation, and efficient resource management. By focusing on versatility, measured design, and information driven insights, manufacturing plants can upgrade production and remain cutthroat in an increasingly computerized world.

FAQs

What is the main component of an effective automation factory model?

The adaptability of the layout and the utilization of advanced automation innovations are pivotal for adapting to growing production demands.

Why is resource streamlining important?

Optimizing resources guarantees that production is sustainable, financially savvy, and minimizes squander, contributing to long haul profitability.

What difficulties are normal while implementing automation?

High initial expenses, complex integration, and ongoing maintenance are normal difficulties while setting up a mechanized factory.

How does secluded design add to adaptability?

Measured production units permit the factory to expand incrementally, ensuring smooth development without disrupting existing cycles.

How could information driven choices further develop factory performance?

Constant information enhances processes, foresee maintenance, and further develop production efficiency, reducing personal time and maximizing result.